Introduction

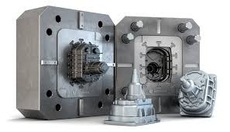

In the rapidly evolving electric mobility industry, choosing the right manufacturing method is key to ensuring product strength, durability, and precision. Pressure Die Casting has become a preferred technique for producing high-performance components like E Rickshaw Shocker and Electric Scooter Body Parts. This process involves injecting molten metal into a steel mold under high pressure, resulting in components that are lightweight, strong, and dimensionally accurate. Its ability to produce large quantities with consistent quality and minimal post-processing makes it cost-effective and ideal for electric vehicle parts.

1. Superior Strength and Durability

The first and most important benefit of Pressure Die Casting is its ability to produce parts with excellent mechanical strength. When manufacturing E Rickshaw Shocker and Electric Scooter Body Parts, durability is a must. These parts go through continuous stress, bumps, and environmental exposure.

With Pressure Die Casting, molten metal is injected into a high-pressure mold. This process allows the metal to fill even the tiniest spaces, creating solid and dense parts. As a result, the final products are less likely to break or wear out over time.

This quality makes Pressure Die Casting ideal for components that require long-term performance in tough conditions.

2. Precision and Accuracy in Manufacturing

Another major advantage of using Pressure Die Casting is the ability to produce parts with very tight tolerances. In simpler terms, it means the parts come out almost exactly as designed, with minimal need for extra cutting or finishing.

In the case of E Rickshaw Shocker and Electric Scooter Body Parts, precision is crucial. The shocks must fit perfectly into their mounts, and body panels must align correctly to ensure smooth assembly.

Thanks to this casting method, manufacturers get high-quality, dimensionally accurate parts in every cycle. This not only saves time but also reduces material waste.

3. Faster Production Rates

Time is money, especially in manufacturing. One of the standout features of Pressure Die Casting is its fast production speed. Since the molds are made of hardened steel and can withstand repeated use, a large number of parts can be produced in a short amount of time.

For industries making E Rickshaw Shocker and Electric Scooter Body Parts, faster production means quicker delivery to the market. This is highly beneficial in meeting the increasing demand for electric vehicles.

Also, the consistent production quality reduces the chances of rework, helping companies keep up with schedules and maintain customer satisfaction.

4. Cost-Effective for Bulk Manufacturing

While the initial setup of Pressure Die Casting (like mold creation) may require investment, the process becomes very cost-effective when producing parts in large volumes. Once the dies are made, the cost per part drops significantly.

This is especially important for E Rickshaw Shocker and Electric Scooter Body Parts, which are produced in high quantities for the booming electric vehicle market. Manufacturers save money on both labor and raw materials, making it an affordable solution in the long run.

5. Better Surface Finish and Aesthetic Quality

Apart from strength and precision, the final appearance of parts also matters—especially in Electric Scooter Body Parts. These parts need to look clean, polished, and professional.

With Pressure Die Casting, parts come out with a smooth surface that often requires little to no machining. This not only enhances the visual appeal but also makes further processes like painting or coating easier and more effective.

A better surface finish also improves corrosion resistance, which is critical for the lifespan of E Rickshaw Shocker and Electric Scooter Body Parts in outdoor use.

Bonus Benefit: Material Versatility

An added advantage of Pressure Die Casting is the wide variety of materials it supports, including aluminum, magnesium, and zinc alloys. This gives manufacturers the flexibility to choose the right material based on the strength, weight, and cost requirements of their E Rickshaw Shocker and Electric Scooter Body Parts.

Conclusion

In summary, Pressure Die Casting offers a wide range of benefits that make it the perfect choice for manufacturing E Rickshaw Shocker and Electric Scooter Body Parts. From high strength and precision to cost-effectiveness and fast production, this method stands out as a smart and sustainable manufacturing solution.

As the demand for electric vehicles continues to grow, companies like Auto Die Cast (India) are helping shape the future of mobility through expert craftsmanship and reliable die casting solutions.