Introduction

In today’s growing industries, many metal parts need to be strong, lightweight, and made in large quantities. One of the best ways to make such parts is through Pressure Die Casting. This process involves forcing molten metal into a mold using high pressure. Once the metal cools, it forms a solid part with a perfect shape. From engine components to mobile phone covers, pressure die casting is used to make high-quality parts quickly, with less waste, and at a lower cost. It’s especially useful for making parts that require fine detail and strength.

Auto Die Cast (India) is a leading manufacturer of high-quality E-Rickshaw parts made using advanced Pressure Die Casting techniques. Their components are lightweight, durable, and designed with great precision. This method allows them to produce large volumes of parts quickly while reducing material waste. Their reliable and cost-effective solutions have made them a trusted name in the electric vehicle industry, meeting the growing demand for strong and efficient metal parts.

What Is Pressure Die Casting?

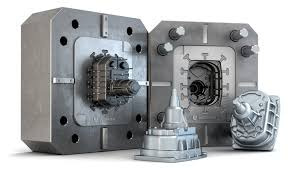

Pressure Die Casting is a trusted way of making strong and perfectly shaped metal parts. In this method, hot liquid metal is pushed into a steel mold using high pressure. After the metal cools, it takes the exact shape of the mold with a clean and smooth surface.

This process is widely used by Pressure Die Casting Manufacturers because it allows them to produce a large number of parts quickly and with less waste. It’s perfect for making items that need to be the same in size and shape every time, like parts used in vehicles, machines, and electronics.

How Does Pressure Die Casting Work?

The process is simple and fast. Here’s how it works:

- Preparing the Mold: The mold is cleaned and sprayed with a lubricant.

- Injecting the Metal: Hot liquid metal is pushed into the mold using a machine.

- Cooling: The metal cools and becomes solid inside the mold.

- Opening the Mold: The mold opens, and the part is removed.

- Trimming: Extra metal is trimmed from the finished part.

This entire process takes only a few seconds, which is why Pressure Die Casting Manufacturers in Delhi prefer it for large-scale production.

Types of Pressure Die Casting

There are two main types of pressure die casting:

A. Hot Chamber Die Casting

- Used for metals like zinc and magnesium.

- The machine parts are in direct contact with molten metal.

- Commonly used for small parts.

B. Cold Chamber Die Casting

- Used for metals like aluminum and copper.

- The molten metal is poured into a chamber before being injected into the mold.

- Ideal for bigger and stronger parts.

Both methods are widely used by Top Pressure Die Casting Manufacturers in Delhi to suit different industries and materials.

Materials Used in Pressure Die Casting

Some common metals used in this method are:

- Aluminum: Lightweight and rust-resistant. Used in cars and airplanes.

- Zinc: Good for small, detailed parts. Strong and affordable.

- Magnesium: Very light. Used in electronics and mobile phones.

- Copper Alloys: Strong and heat-resistant. Used in electrical items.

Many Pressure Die Casting Suppliers in India choose metals depending on the product’s purpose and required strength.

Benefits of Pressure Die Casting

There are many reasons why Pressure Die Casting Manufacturers use this method:

- Fast Production: Many parts can be made quickly.

- Accurate Shapes: Parts come out with exact measurements.

- Smooth Surface: Little or no polishing is needed.

- Low Cost per Part: Once the mold is ready, each part is cheaper to make.

- Strong and Durable: Parts are strong and long-lasting.

This is why Pressure Die Cast Exporters and Suppliers in India prefer this method to serve industries like automotive, electronics, and machinery.

Industries That Use Pressure Die Casting

Pressure Die Casting is used in many industries, including:

- Automobiles: Engine parts, gearboxes, and wheels.

- Electronics: Laptop and phone bodies, camera parts.

- Appliances: Washing machines, mixers, and other home products.

- Lighting: Frames and covers for lights.

- Industrial Machines: Parts for factory tools and heavy equipment.

Pressure Die Casting Manufacturers in Delhi produce many of these parts and export them globally.

Why Pressure Die Casting Is Preferred by Manufacturers

Manufacturers prefer this method for several reasons:

- Saves time and money on large orders.

- Reduces material waste.

- Improves the appearance of the final product.

- Can be used to make very detailed and thin parts.

Pressure Die Casting Exporters often highlight these benefits to meet global quality standards and customer needs.

Choosing the Right Pressure Die Casting Manufacturers

When looking for a trusted manufacturer, consider these points:

- Years of experience in pressure die casting.

- Type of metals and products they specialize in.

- Ability to deliver large quantities on time.

- Certification and global standards followed.

- Client feedback and reviews.

Many Top Pressure Die Casting Manufacturers in Delhi are known for offering reliable and custom solutions across different industries.

Growth of Pressure Die Casting in India

India is becoming a hub for Pressure Die Casting Manufacturers. With advanced machines, skilled workers, and a focus on quality, the country is meeting the rising demand for precision parts.

Pressure Die Casting Suppliers from India are now serving industries in the USA, Europe, and other regions. This growth is making Indian companies strong global competitors.

Especially in cities like Delhi, many Pressure Die Cast Exporters and Suppliers in India are offering world-class solutions.

Export Opportunities for Indian Pressure Die Casting Companies

With increasing global demand, Indian companies are exporting casted parts to various countries. Their focus on quality, timely delivery, and cost-effective pricing gives them an edge.

Many Pressure Die Casting Exporters offer custom solutions to meet the needs of clients in the automobile, medical, and electronics industries.

Pressure Die Casting Manufacturers in Delhi are becoming global partners for companies looking for dependable casting services.

Frequently Asked Questions (FAQs)

1. What is Pressure Die Casting used for?

It is used to make accurate and strong metal parts quickly and in large numbers.

2. How do Pressure Die Casting Manufacturers ensure quality?

They use advanced machines, strict checks, and test every part for strength and size.

3. Are aluminium parts made using Pressure Die Casting?

Yes, most Aluminium Die Casting Manufacturers use this method to make lightweight and strong parts.

4. Which industries need Pressure Die Casting the most?

Automobiles, electronics, home appliances, and lighting industries use it widely.

5. Why is Pressure Die Casting preferred for exports?

Because it makes high-quality parts in large numbers, and Auto Die Cast (India) is known for supplying such parts worldwide.

Conclusion

Pressure Die Casting is a smart and efficient way to produce high-quality metal parts that are strong, lightweight, and accurate. It’s widely used in many industries, from cars and electronics to machinery and household goods. The process is fast, cost-effective, and highly reliable—making it a top choice among manufacturers worldwide. Whether you're a business looking for trusted partners or someone curious about manufacturing, understanding this process can help you see how everyday metal items are made.

If you're seeking reliable and experienced service, Auto Die Cast (India) is one of the trusted names in the field, offering expert pressure die casting solutions across various sectors.