Introduction to Brake Drum

The brake drum seldom draws a glance, yet it quietly performs a vital job in any vehicle's stopping system. Normally cast from durable grey-iron, the cylindrical part rotates with the wheel, and once the driver presses the pedal, curved shoes push outward and squeeze its inner wall. That squeeze generates friction, cutting speed or halting the car within moments. Brake drums still rule the brake setups of heavy trucks, buses and trailers because they soak up huge heat without fading. A few older sedans and light city cars keep them for their straightforward design and consistent grip. Even tiny electric scooters hide little drums inside the wheel hubs; that slim layout saves room and mass while delivering trustworthy stopping power.

What Do Brake Drum Manufacturers Do?

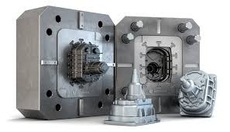

Drum-makers oversee every detail, from first sketch to casting, machining, finishing and tough on-road tests that check the part for shock, searing heat and years of real service. They choose specific cast-iron grades or modern alloy steel purposely matched for strength, heat flow and wear resistance.

The manufacturing process involves:

- Designing the brake drum to meet specific vehicle needs

- Melting and molding metal into the required shape

- Machining and finishing for smooth and accurate fitting

- Testing under pressure to ensure safety and performance

Good brake drum manufacturers always follow industry standards and quality checks to ensure their products are safe to use and long-lasting.

Why Quality Matters in Brake Drum Manufacturing

Using a high-quality Brake Drum is not just about smooth performance—it’s about safety. A poor-quality brake drum can crack, overheat, or wear out quickly, putting the driver and passengers at risk.

That’s why Brake Drum Manufacturers must:

- Use the best materials

- Perform safety and durability testing

- Ensure the drum fits perfectly with other brake system parts

- Meet vehicle-specific size and performance requirements

Additionally, with the rise of modern vehicles and Electric Scooter Body Parts, manufacturers are now focusing on making lighter yet stronger drums that offer high performance without adding weight.

Export Market for Brake Drum Manufacturers

Today, many Brake Drum Manufacturers export their products to other countries. The demand for reliable brake drums is high in both developed and developing markets, especially in areas where heavy-duty transport vehicles are widely used.

Key factors driving exports:

- Growth in the automotive industry

- Increased demand for aftermarket parts

- Rising need for safety and high-performance products

- Expansion of Electric Scooter Body Parts industry globally

Countries across Africa, Southeast Asia, Europe, and the Middle East rely heavily on exports from India and China, where skilled labor and advanced production facilities keep costs competitive and quality high.

How to Choose the Right Brake Drum Manufacturer

Choosing the right Brake Drum Manufacturers is essential for ensuring performance and safety. Here are a few tips:

- Check their certifications: Make sure they follow ISO and other international standards

- Look at their experience: More years in the business often means more reliability

- Ask about customization: Some manufacturers offer made-to-order brake drums

- Inspect product range: A good supplier offers drums for all vehicle types including Electric Scooter Body Parts

- Evaluate their export quality: Especially if you're sourcing parts for global use

Taking the time to research and select a trusted supplier can save time, cost, and improve product quality.

The Link Between Brake Drums and Electric Scooter Body Parts

The demand for Electric Scooter Body Parts has increased rapidly in recent years. Lightweight and efficient braking systems are critical for electric scooters, and manufacturers are now designing brake drums specifically suited for these modern vehicles.

Brake drums used in scooters are generally smaller, lighter, and specially coated to resist rust. As more urban commuters shift to electric transportation, brake drum manufacturers are adapting to serve this fast-growing segment.

In fact, many companies now offer custom brake solutions for manufacturers of electric bikes and scooters, highlighting the growing importance of this market.

Future of Brake Drum Manufacturing

The future of Brake Drum production looks promising with several advancements in place:

- Automation and robotics in manufacturing

- Use of eco-friendly materials

- Smart drums with sensors for performance monitoring

- Expansion into lightweight solutions for electric scooter body parts

These innovations will help manufacturers improve product life, reduce cost, and support the growing shift toward electric and hybrid vehicles.

Conclusion

Whether fitted to a rugged delivery truck or the newest electric scooter, high-quality brake drums play a crucial role in vehicle safety and performance. As a result, brake-drum manufacturers occupy a central position in every reliable braking system, providing the toughness and uniformity that keep vehicles operating smoothly. With export volumes on the rise and emerging markets-for example, parts for electric scooters-growing rapidly, the industry continues to adjust to advancing technology and changing customer demands.

For consistent quality and long-lasting service, Auto Die Cast (India) stands out as a dependable partner, renowned for excellence in brake-drum manufacturing and timely deliveries around the world.