Aluminium Die Casting is one of the most trusted methods for making strong, lightweight, and perfectly shaped metal parts used in everyday products. From car engines to mobile phones and even aircraft parts—this process powers many industries like automotive, electronics, aerospace, and construction. It is also widely used in manufacturing precision parts for E Rickshaw, ensuring durability and performance. Its growing demand comes from a powerful mix of speed, accuracy, and cost-effectiveness. By injecting molten aluminium into a steel mold under high pressure, Aluminium Die Casting Manufacturers can produce large volumes of parts with smooth finishes and exact shapes—perfect for high-performance applications.

With the rising demand for lightweight yet durable materials, Aluminium Die Casting has become essential in today's industrial world. It plays a vital role in producing precise and strong components for various sectors such as automotive, electronics, aerospace, and infrastructure. Companies like Auto Die Cast (India) utilize advanced high-pressure techniques to mold aluminium into complex shapes, ensuring efficient, cost-effective, and high-volume production—making the process a cornerstone of modern manufacturing

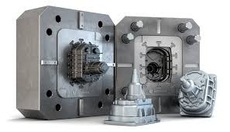

Understanding the Aluminium Die Casting Process

The Aluminium Die Casting process involves injecting molten aluminium into a steel mold at high speed and pressure. Here's a simple breakdown:

Step-by-Step Process:

- Melting Aluminium: High-purity aluminium is melted in a furnace.

- Injection into Mold: The molten metal is injected into a precision steel die using a die casting machine.

- Cooling and Solidifying: The metal cools and takes the shape of the mold.

- Ejection: Once cooled, the casting is ejected from the mold.

- Trimming and Finishing: Excess material is removed, and the part is polished or machined as needed.

This process is ideal for creating high-volume parts quickly and accurately, and it ensures minimal material waste.

Key Benefits of Aluminium Die Casting

Using Aluminium Die Casting comes with several advantages that make it a top choice for both small-scale and large-scale industries.

Top Benefits:

- Lightweight Yet Strong: Aluminium parts are lighter than steel but still highly durable.

- High Dimensional Accuracy: Excellent for precision components.

- Fast Production: Suitable for mass production at high speeds.

- Cost-Effective: Less material waste and reduced labor costs.

- Good Surface Finish: Reduces the need for additional finishing.

- Corrosion Resistant: Ideal for automotive and marine environments.

These benefits help Aluminium Die Casting Manufacturers produce parts that meet exact specifications while reducing cost and time.

Common Applications of Aluminium Die Casting

From household items to high-end automobiles, Aluminium Die Casting plays a key role in shaping modern industries.

Where It's Used:

- Automotive Industry: Engine parts, gearboxes, and transmission housings.

- Aerospace: Lightweight and strong aircraft parts.

- Consumer Electronics: Housings for phones, laptops, and other gadgets.

- Industrial Equipment: Pumps, valves, and machinery components.

- Construction: Fittings, brackets, and frames.

The versatility of aluminium makes it ideal for applications requiring strength without adding weight.

Role of Aluminium Die Casting Manufacturers

Reliable Aluminium Die Casting Manufacturers ensure consistent quality, precision, and durability in every part produced. They follow global standards and use advanced machinery to produce complex parts quickly.

In recent years, Aluminium Die Casting Manufacturers in Delhi and Aluminium Die Casting Manufacturers in India have gained popularity for offering world-class quality with competitive pricing. Many businesses now trust these manufacturers for both domestic and international supply.

Aluminium Die Casting Suppliers and Exporters

While manufacturers produce the components, Aluminium Die Casting Suppliers and Aluminium Die Casting Exporters play a major role in making these parts available across different markets.

These suppliers help in:

- Bridging the gap between manufacturer and end-user

- Handling packaging, shipping, and logistics

- Ensuring quality checks during transportation

With the rise in global demand, Indian Aluminium Die Casting Exporters are now supplying to countries across Europe, Asia, and North America.

How to Choose the Right Aluminium Die Casting Partner

When selecting the right partner for your aluminium die casting needs, consider these key factors:

- Experience & Reputation: Choose manufacturers with proven track records.

- Technology Used: Look for those using advanced CNC and automated machines.

- Certifications: ISO or other quality certifications ensure standard practices.

- Production Capacity: Check if they can handle your order volume.

- Customer Support: Timely communication is key to a smooth process.

Future of Aluminium Die Casting Industry

The future of Aluminium Die Casting is promising, thanks to rising demand in electric vehicles, consumer electronics, and smart infrastructure.

Key innovations expected:

- Eco-friendly casting techniques

- Use of recycled aluminium

- 3D printing for mold creation

- Automation and AI for precision control

As technology advances, Aluminium Die Casting Manufacturers will continue to adopt newer methods to stay competitive and eco-conscious.

Frequently Asked Questions (FAQs)

Q1. What is the main advantage of using Aluminium Die Casting?

It provides high strength, light weight, and precision at a low cost.

Q2. Why choose Aluminium Die Casting over other casting methods?

Because it offers faster production, better surface finish, and excellent dimensional control.

Q3. Who are the trusted Pressure Die Casting Manufacturers in India?

Many trusted Pressure Die Casting Manufacturers in India, like Auto Die Cast (India), offer high-quality solutions with global certifications

Q4. Where can I find the best Aluminium Die Casting Manufacturers in Delhi?

You can find several ISO-certified manufacturers in Delhi, such as Auto Die Cast (India), offering both domestic and international services.

Q5. Are Aluminium Die Casting Exporters reliable for global supply?

Yes, top exporters ensure proper quality control and safe shipping across borders.

Conclusion

In summary, Aluminium Die Casting is a fast, efficient, and economical process used across many industries. Its benefits—like strength, accuracy, and lightweight properties—make it the go-to solution for mass production. Whether you're looking for small parts or complex industrial components, working with the right manufacturer ensures quality and reliability. The growing presence of Aluminium Die Casting Manufacturers in India, especially in hubs like Delhi, is a clear sign of the industry’s trust in Indian manufacturing excellence.

For businesses looking for a trustworthy partner, Auto Die Cast (India) stands out as a reliable and experienced name in the industry.