Aluminium die casting is a high-precision manufacturing process widely used to create strong, lightweight, and detailed metal components. When combined with pressure die casting techniques, it ensures consistent quality, fast production, and minimal material waste—making it ideal for industries like automotive, aerospace, and electronics. This process uses molten aluminium, injected into steel molds under high pressure, to produce complex shapes with tight tolerances and excellent surface finishes. With growing demand for durable and cost-effective metal parts, aluminium die casting has become the preferred choice for manufacturers looking to balance performance, efficiency, and design flexibility.

What is Aluminium Die Casting?

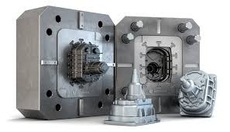

Aluminium die casting is a method where molten aluminium is injected into a mold or die under high pressure. The result is a solid aluminium part with a detailed shape and smooth surface. This process helps in making strong and lightweight products quickly and efficiently.

Some common examples of aluminium die casting products include engine parts, electrical housings, furniture fittings, and more.

Why Pressure Die Casting is Used

Pressure die casting uses force to inject molten aluminium into steel dies at high speed. This pressure helps fill even the smallest sections of the mold and reduces the chances of air pockets or defects. This makes pressure die casting perfect for creating parts that require fine details and close tolerances.

Step-by-Step Process of Aluminium Die Casting

Let’s walk through each stage of the aluminium die casting process using pressure die casting techniques:

1. Preparing the Aluminium Die Casting Material

The process starts by choosing the right aluminium die casting material. The aluminium alloy is selected based on the strength, heat resistance, and surface finish needed for the product. Once chosen, the metal is melted in a furnace at high temperature (around 660°C).

2. Die Preparation

While the metal is melting, the steel mold (die) is cleaned and sprayed with a lubricant. This lubricant helps in two ways:

- It allows the smooth flow of molten aluminium.

- It helps release the solid part easily after cooling.

Dies are made from durable steel and can be reused many times, which reduces overall costs.

3. Injection into the Die

The molten aluminium is then forced into the die using a pressure die casting machine. The machine applies pressure (usually between 1,500 and 25,000 psi) to ensure that the metal fills every part of the mold.

This is the key step that defines Pressure Die Casting. It ensures high precision and consistent product quality.

4. Cooling and Solidification

Once the die is filled with molten aluminium, it is allowed to cool and solidify. This stage is quick and ensures the part holds its shape properly. The die is then opened, and the finished part is ejected.

5. Trimming and Finishing

After ejection, excess metal (known as flash) is removed through trimming. The parts are then polished, sanded, or coated based on the requirements. Some parts may go through machining for extra accuracy.

At this stage, you get a complete aluminium die casting product ready for use or assembly.

Benefits of Aluminium Die Casting Using Pressure Die Casting

- High Precision: Accurate, complex shapes are possible.

- Speed: Rapid production for high-volume needs.

- Strength: Aluminium parts are strong yet lightweight.

- Consistency: Uniform quality in every product.

- Cost-effective: Reusable dies reduce long-term expenses.

Where is Aluminium Die Casting Commonly Used?

The demand for Aluminium Die Casting Manufacturers is growing across many sectors. It’s widely used in:

- Automobile parts like engine blocks and gearbox housings.

- Electronics like enclosures and connectors.

- Consumer goods such as kitchen appliances and hardware.

You can easily search for aluminium die casting near me to find local suppliers offering custom services for your needs.

Types of Aluminium Die Casting Machines

There are mainly two types of machines:

- Hot Chamber Machines: Used for metals with lower melting points.

- Cold Chamber Machines: Perfect for aluminium, since it melts at a higher temperature.

A cold chamber aluminium die casting machine is more common for pressure die casting of aluminium parts.

Things to Consider When Choosing Aluminium Die Casting Services

- Quality of aluminium die casting material

- Experience of the aluminium die casting manufacturers

- Type and size of aluminium die casting machine

- Delivery time and customization options

- Availability of post-processing and finishing services

For the best outcomes, always work with trusted manufacturers who offer precision and reliability.

Conclusion

Aluminium die casting using pressure die casting techniques is an advanced, efficient, and reliable way to produce top-quality aluminium components. From material preparation to final finishing, each step is important for achieving a strong and accurate product.

Whether you’re looking for large-scale production or custom parts, this method offers excellent results. If you’re searching for aluminium die casting near me, make sure the company you choose has the right tools, experience, and machines to meet your needs.

For expert services and trusted quality, Auto Die Cast (India) is a name you can count on.